In 2019, a study by McGill University sent shockwaves through the beverage industry. The researchers found that a single plastic tea bag, when steeped at brewing temperature, released approximately 11.6 billion microplastics and 3.1 billion nanoplastics into the cup.

For tea brands, this was a wake-up call.

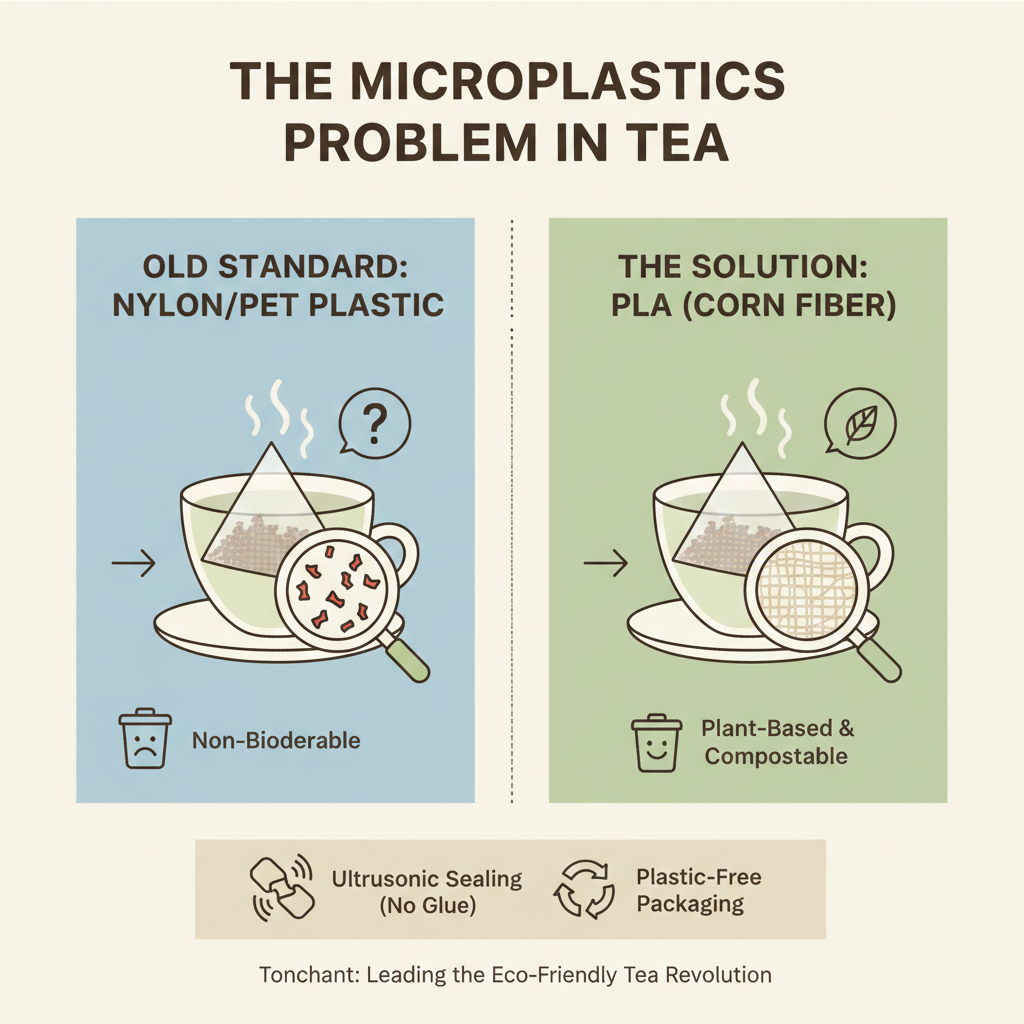

For decades, the “silky” pyramid tea bag made of food-grade Nylon or PET was the industry standard for premium loose-leaf tea. It looked great and allowed the leaves to expand. But as consumer awareness grows, the definition of “premium” is shifting.

Premium no longer just means “tastes good”; it means “safe for me and safe for the planet.”

If you are a tea brand owner or a roaster expanding into tea, addressing the microplastic issue is your biggest opportunity to build trust. Here is how you can transition your production line to a plastic-free future.

The Problem with “Hidden” Plastics

It isn’t just the obvious nylon bags that are the problem. Even traditional paper tea bags often contain polypropylene fibers to help them heat-seal, or use epichlorohydrin to strengthen the paper when wet.

When boiling water hits these materials, they don’t melt, but they can degrade at a microscopic level. Your customers are drinking high-mountain Oolong or organic Earl Grey for health—the last thing they want is a side of synthetic polymers.

The Solution: PLA (Corn Fiber) Mesh

The most effective way to eliminate microplastics while keeping the luxury appeal of the pyramid bag is to switch to PLA (Polylactic Acid).

Often marketed as “Corn Fiber,” PLA is a bioplastic derived from renewable plant starches (usually corn or sugarcane).

-

Visual Appeal: It looks identical to nylon—transparent, glossy, and strong.

-

The Difference: It is not petroleum-based. Under industrial composting conditions, it breaks down into water, CO2, and biomass.

-

The Safety: It is naturally bacteriostatic and does not release toxic microplastics when heated.

Industry Trend: At Tonchant, we have seen a 300% increase in inquiries for PLA mesh rolls in the last two years. The market is moving, and it is moving fast.

It’s Not Just Material—It’s the Method

Here is a technical detail that many brands overlook: How do you seal the bag?

You can buy the best biodegradable mesh in the world, but if you use a chemical adhesive (glue) to close the bag, you are re-introducing contaminants into the cup.

This is why Ultrasonic Sealing Technology is non-negotiable for eco-friendly packaging.

Ultrasonic machines use high-frequency vibrations to bond the materials together instantly. No heat bars, no glue, no metal staples.

-

The Result: A clean, minimal seam that is 100% physically bonded.

-

Tonchant’s Expertise: We don’t just supply the PLA mesh. We manufacture the Automatic Tea Bag Packing Machines that utilize this ultrasonic technology. We ensure that the machine is perfectly calibrated to the specific melting point of the corn fiber mesh, preventing tears or weak seals.

Is the Switch Worth the Cost?

Let’s be honest: PLA materials are currently more expensive than standard Nylon or PET. However, consider the “Brand Risk” cost.

If a competitor points out that your bags are plastic, or if a customer asks, “Is this compostable?” and you have to say no, you lose that customer forever.

Switching to biodegradable packaging allows you to print “Plant-Based,” “Plastic-Free,” and “Compostable” on your boxes. In the premium tea market, these claims justify a higher price point that easily covers the marginal increase in material costs.

How to Get Started

You don’t need to overhaul your entire supply chain overnight.

-

Test the Material: Ask us for a sample kit of our PLA Corn Fiber mesh. Brew it yourself. Check the transparency and the taste neutrality.

-

Check Your Machinery: If you have existing packing machines, they may need adjustment to run PLA. Our engineers can guide you on temperature and tension settings.

-

Start with a Line: Launch a specific “Eco-Collection” using our pre-made empty PLA bags to test market response.

Ready to remove microplastics from your brand? [Contact Tonchant] today to discuss PLA mesh rolls, custom tags, and ultrasonic packaging solutions.

Post time: Jan-23-2026