Preserving the perfect roasted taste of single-serve drip coffee depends not only on the packaging itself but also on the grounds. Tonchant’s drip coffee filter bag solutions are designed to lock in aroma, control outgassing, and extend shelf life, enabling professional roasters and foodservice brands to deliver a memorable first-cup experience every time.

Why Oxygen Barrier Bags Are Important

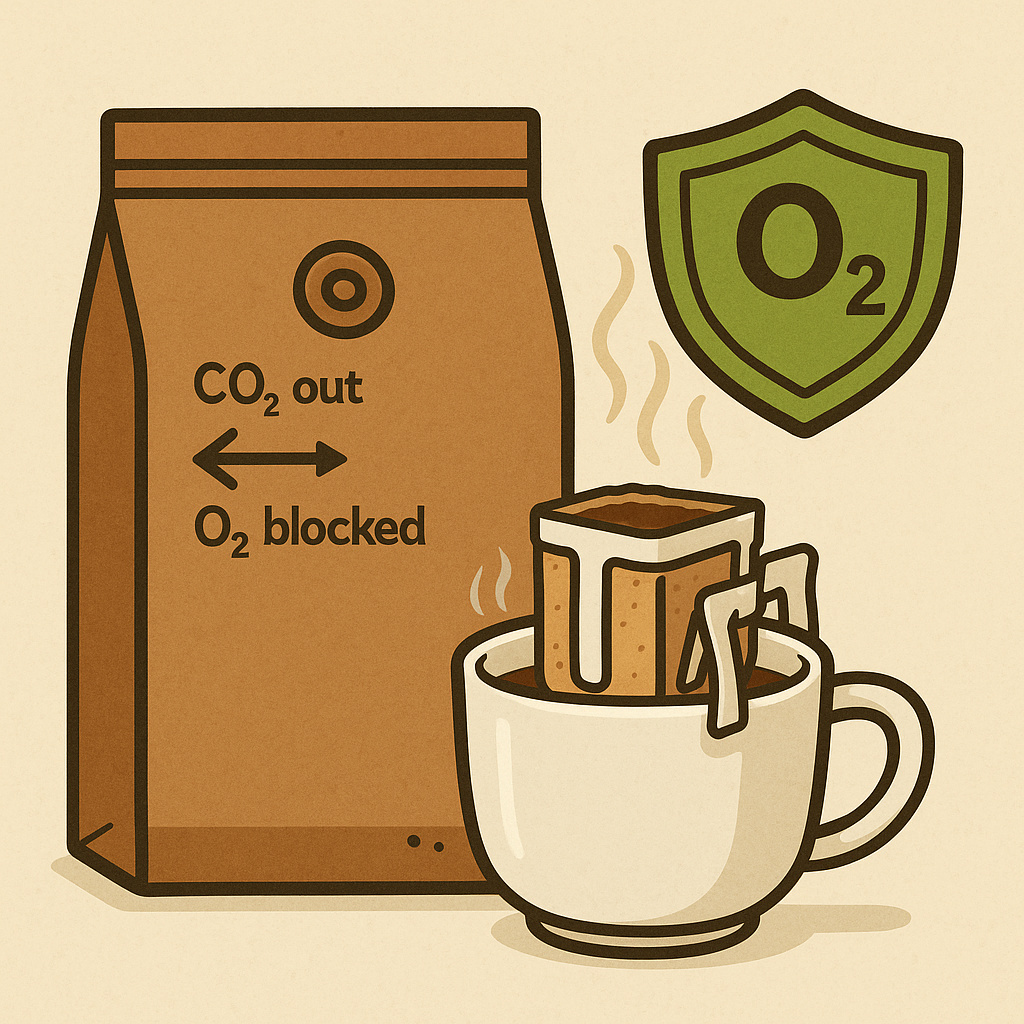

Roasted coffee is fragile: volatile aromatics and oils quickly evaporate or oxidize when exposed to air. High-performance oxygen-barrier packaging can slow this process, preserving the aroma and flavor of the bag throughout storage in the warehouse, on the retail shelf, and ultimately to the consumer. For single-serve drip coffee bags, which release bursts of aroma upon opening, effective oxygen barrier protection is crucial to distinguishing “fresh” from “stale.”

Key Features of Tonchant Isolation Bags

• High-barrier constructions: Multi-layer laminates utilizing EVOH, aluminum foil, or advanced metallized films to minimize oxygen permeation.

• One-way exhaust valve: allows carbon dioxide to escape after baking, but does not allow oxygen to re-enter, preventing the bag from expanding and deteriorating.

• Compatible Inner Bags: Pre-folded, unbleached or bleached filter papers nested within sealed barrier bags for maximum protection.

• Resealable options and tear notches: Consumer-friendly features that preserve freshness after opening.

• Custom printing and branding: Digital and flexographic printing on barrier films to achieve desired visual effects for retail.

Material selection and trade-offs

Aluminum/foil laminates offer the strongest barrier to oxygen and light, making them ideal for long-distance export routes or highly aromatic micro-batches.

EVOH or high-barrier monofilm structures provide excellent protection while supporting easier recycling paths in markets with single-stream capabilities.

For brands prioritizing compostability, Tonchant recommends using PLA-lined kraft paper fabrics and careful route planning—these work best with short, local supply chains.

Performance testing and quality control

Tonchant tests barrier bags for oxygen transmission rate (OTR), water vapor transmission rate (MVTR), valve performance, and seal integrity. Each production batch undergoes sample brewing trials and simulated shipping tests to ensure the coffee aroma, in-cup clarity, and bag durability meet the expectations of baristas and retailers.

Design and shelf advantages

Barrier bags don’t have to look industrial. Tonchant’s prepress team can adjust the graphics to create matte, soft-touch, or metallic finishes, and can incorporate QR codes, tasting notes, and roast dates into the design. A well-designed bag protects the product while telling the coffee’s origin story—critical for specialty coffee consumers.

Logistics, delivery times and customization

Tonchant supports small-scale prototype production and can scale to larger flexo orders as demand grows. A typical workflow includes rapid sample approval, barrier material selection, valve specification, and pilot production for shelf testing. The company coordinates printing, bag forming, and valve insertion according to a strict quality control schedule to ensure predictable lead times.

Sustainability and end-of-life considerations

Barrier performance and sustainability can sometimes be at odds. Tonchant helps brands find the right balance – choosing recyclable mono-material packaging where recycling facilities are available, or compostable paper packaging at local retail locations with industrial composting facilities. Clearly communicating information to consumers about disposal and collection is part of the solution.

Who Benefits Most from Drip Bag Barrier Bags

Roasters export single-origin micro-lots of coffee that need to maintain a long shelf life during transportation.

The subscription service guarantees freshness to the baking date when goods arrive.

Hotels, airlines, and hospitality brands deliver premium single-serve pouch packaging in challenging storage environments.

Retailers want shelf-stable, high-impact, single-serve products that retain their aroma after opening.

Get started with Tonchant Testing Barrier Solutions

If you’re launching a drip bag line or upgrading an existing pouch product, it’s worth conducting comparative shelf and sensory testing first. Tonchant offers barrier bag samples, valve options, and print mockups to help you evaluate aroma retention, sealing performance, and shelf appearance before scaling up.

Contact Tonchant today to request samples, technical specifications, and custom production plans for our Oxygen Barrier Drip Filter Bags. Protect aroma, lock in flavor, and make every single cup a true first sip.

Post time: Sep-28-2025