We all know that there is a waste problem in the coffee and tea industry.

For decades, the convenience of individually packaged products—such as tea bags and drip coffee pods—has come at a cost: microplastics and non-recyclable materials ending up in landfills.

But the tide is turning. Today’s consumers will flip the packaging over, looking for certification information, and they’ll ask: “Is this plastic?” and “Can I compost it?”

At Tonchant, we believe packaging manufacturers have a responsibility to lead this transformation. We provide not only materials but also the tools to help brands transition to a more environmentally friendly future without sacrificing quality or freshness.

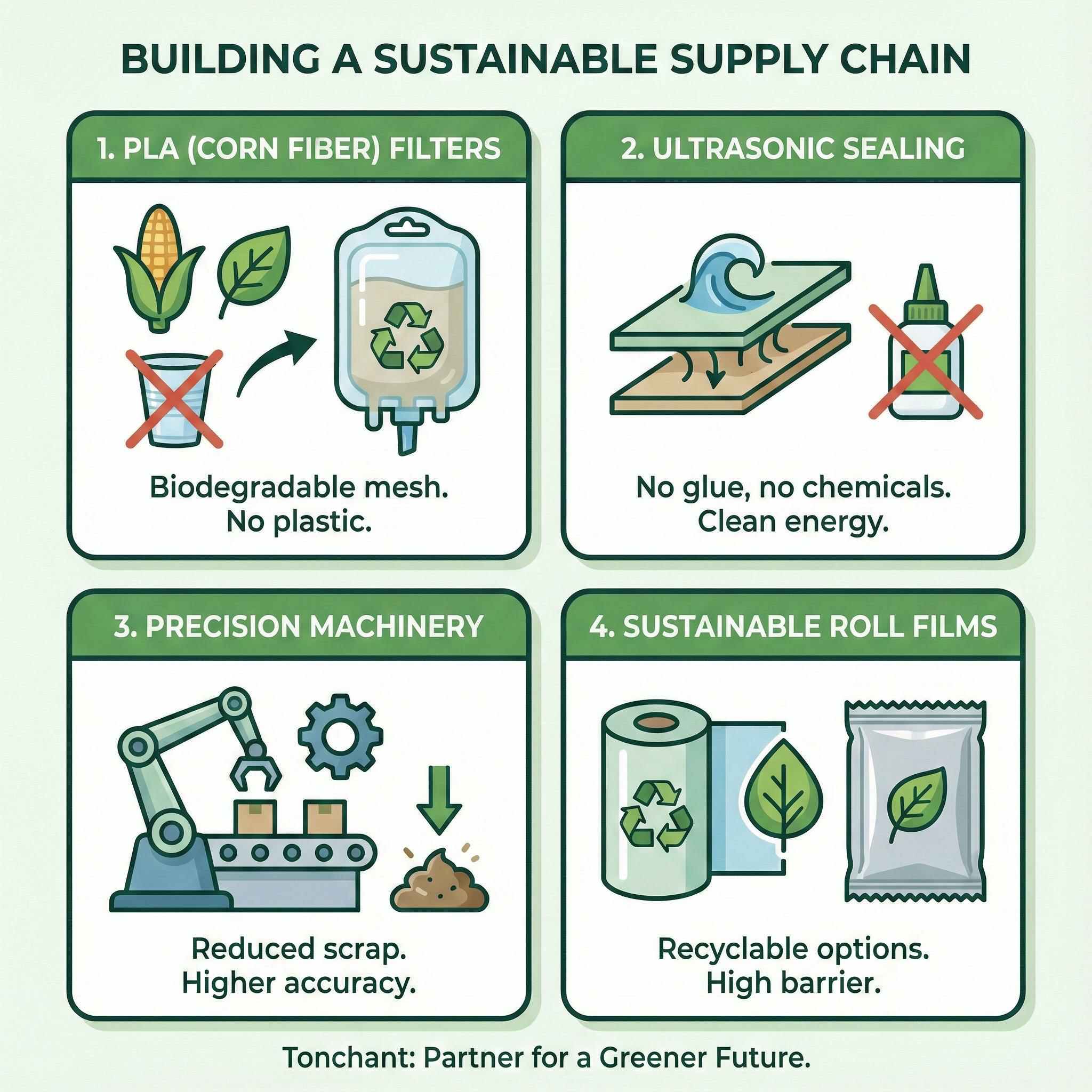

Here’s how we build more sustainable supply chains for our partners.

1. The Shift to PLA (Corn Fiber)

The biggest innovation in our product line is the extensive use of PLA (Polylactic Acid) mesh fabric in the production of coffee drip bags and pyramid-shaped tea bags.

What is it? PLA is often referred to as “corn fiber” because it is derived from renewable plant starches (such as corn or sugarcane) rather than fossil fuels.

Why it matters: It looks and feels like high-grade silk, with excellent transparency and water permeability. However, unlike traditional nylon or polypropylene (PP), PLA is biodegradable and compostable under industrial conditions.

Our Goal: We are actively helping our customers transition from standard plastic filters to PLA filters, enabling them to market their products as “plastic-free” and environmentally friendly.

2. No Glue, No Chemicals: Ultrasonic Technology

Sustainability is not just about materials, but also about how to put them together.

Many traditional packaging methods use adhesives (glue) to seal bags. At Tonchant, we champion Ultrasonic Sealing Technology. Whether it’s our pre-made bags or the automated packaging machines we sell to roasters, we utilize ultrasonic energy to fuse materials together.

-

Zero Adhesives: No chemical glue enters the compost stream (or the customer’s cup).

-

Energy Efficiency: Ultrasonic sealing is instantaneous and is generally more energy-efficient than heat bars that must be kept continuously hot.

3. Reducing Waste Through Precision Machinery

Reducing waste must start on the production line. A poorly calibrated machine that frequently jams or has poor sealing will generate a significant amount of scrap material.

Our engineering team focuses on precision automation. Our packaging machines are designed to handle fragile, environmentally friendly materials—such as difficult-to-seal PLA—with high precision. By reducing error rates and waste in the packaging process, we help factories and roasters minimize their industrial footprint.

4. Sustainable Roll Film Solutions

The outer barrier bag remains the biggest challenge for the industry because it needs to block oxygen to keep coffee fresh—plastics and aluminum do this very well.

However, Tonchant is constantly testing new recyclable and bio-based composite structures. We offer roll-to-roll solutions that reduce plastic usage while maintaining the high barrier properties required for a 12-month shelf life. We work with our customers to find a balance between maximizing product freshness and minimizing environmental impact.

Partner with a Responsible Manufacturer

Sustainable development is a process, not a destination. For B2B buyers, choosing a supplier is no longer solely based on price, but more importantly, on an alignment of values.

If your brand is considering switching to biodegradable filters or exploring more environmentally friendly packaging workflows, we are happy to assist you in understanding the various options available.

Let’s work together to create a greener brand. [Contact Tonchant] to request samples of our PLA filters and learn more about our sustainable production capabilities.

Post time: Dec-26-2025