Opening a coffee shop is the perfect combination of passion and caffeine. You’ve found the perfect green beans, mastered the roasting curve, and designed a logo that looks amazing on Instagram.

But then, we have to face the practical problems of logistics: Packaging.

It’s the physical bridge connecting products and customers. It needs to keep coffee fresh, look professional, and be affordable. For new entrepreneurs, the sheer variety of filters, roll films, and coffee machines can be overwhelming.

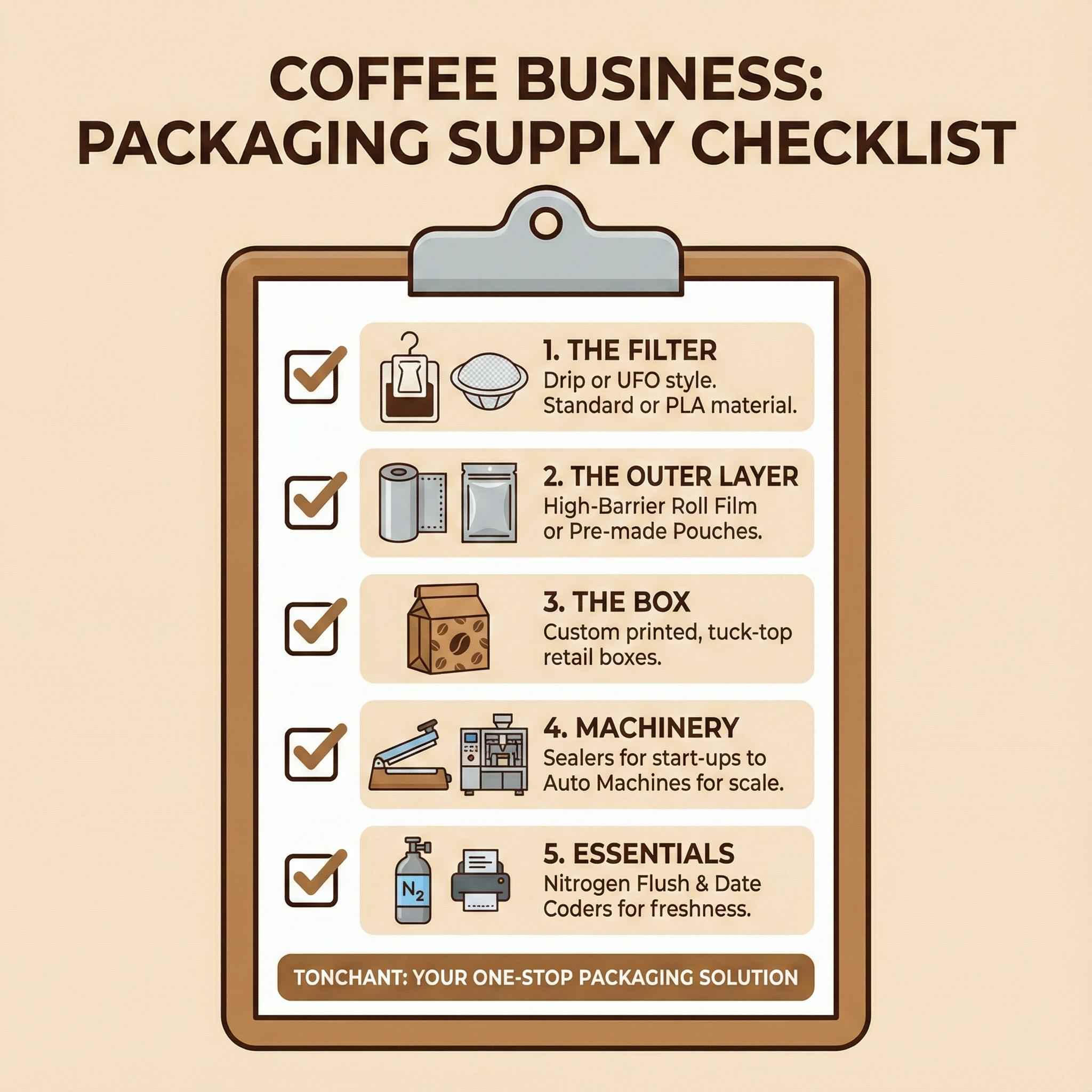

To help you get started smoothly, the Tonchant Team has compiled a comprehensive list of packaging supplies. Whether you’re starting with small-scale manual operations or heading straight for automation, this includes everything you need.

1. The Brewing Mechanism (The Filter)

If you want to enter the single-cup coffee market (which we strongly recommend, as the profit margins are high), you’ll need a container to hold the coffee.

-

Drip Coffee Filter Bags: The standard “drip bag” is the most popular format worldwide. Reliable and easy to use.

-

UFO / Disc Strainer: A high-quality strainer placed on top of a cup. This shape is ideal for premium lines to distinguish different flavors.

Material Selection: Decide as early as possible whether to choose standard food-grade nonwoven fabric (economical) or PLA corn fiber (environmentally friendly).

Tonchant Tip: If you’re a beginner, you can buy pre-made filter bags and fill them by hand. If/when you buy a machine, you will need rolls of filter paper.、

2. Outer Packaging (The Freshness Keeper)

Drip bags cannot be sold “naked”. They need to be sealed in an outer packaging bag to prevent oxygen and moisture from entering.

-

Pre-made Bags: Ideal for manual sealing. The bags are opened on one side when purchased; simply fill and seal.

-

Roll Film: Suitable for automatic packaging machines. It is a continuous roll of printed film that is machine-formed into bags. This type has a lower unit cost but requires specialized machinery.

⚠️ Critical: Barrier Properties Ensure your supplier uses Aluminum foil or a high-barrier VMPET layer. Do not compromise on this; thin, standard plastic can allow oxygen ingress, causing coffee to spoil within weeks.

3. Retail Packaging ( The Box)

If you want to sell in supermarkets or gift shops, you can’t just hand customers small, loose bags. You need a retail box.

-

Cardboard Box: Typically holds 5, 8, or 10 drip bags.

-

Custom Printing: This is your billboard. Please ensure the box design matches the outer packaging bag design for brand consistency.

-

Structure: Look for “foldable” packaging boxes that are easy to assemble quickly by hand or machine.

4. Sealing Equipment (Machinery)

How do you plan to seal these bags? That depends on your budget and volume.

-

Level 1: Handheld Pulse Sealer Inexpensive and easy to operate. Simply press down on the heating element to seal. Suitable for packaging up to 500 bags per week.

-

Level 2: Continuous Sealing Machine Places packaging bags on a conveyor belt. Faster, more professional, and creates a cleaner seal.

-

Level 3: Fully Automatic Packaging Machine Tonchant’s signature product. This machine uses a roll of filter paper and a roll of outer packaging film to complete all operations: shaping, filling coffee, nitrogen filling, sealing, and cutting.

The Reality: If you plan to produce more than 5,000 packaging bags per month, manual sealing will become a bottleneck. Investing in machinery as early as possible can save significant labor costs.

5. The “Hidden” Necessities

Don’t forget those small things; without them, production would stop.

-

Nitrogen Generator: If you want a 12-month shelf life, you will need the nitrogen flushing function to displace oxygen.

-

Date Printer (Inkjet): Most regions require packaging to indicate the “Roasting Date” or “Best Before” date. Our automated machines have this function built-in.

-

Shipping Boxes: Sturdy corrugated boxes are used to transport your products to distributors without crushing them.

Why is Procurement So Difficult? (And How to Solve It)

For a newly opened coffee shop, the biggest challenge lies in managing five different suppliers simultaneously: one for filter paper, one for printed packaging bags, one for cardboard boxes, and one for machinery.

The risk? If the bag and box sizes don’t match, or the printed film isn’t compatible with the machine, you have a real problem.

The Tonchant Solution

We are a one-stop manufacturer. We ensure compatibility across the board:

-

The filter matches the outer bag size perfectly.

-

The outer packaging bag fits snugly into the retail box.

-

Our roll films and filter rolls are tested and perfectly compatible with our packaging machines.

Ready to get everything on your list done in one go? [Contact Tonchant Today] Tell us your start-up plans, and we’ll help you create a budget-friendly starter package.

Post time: Dec-26-2025