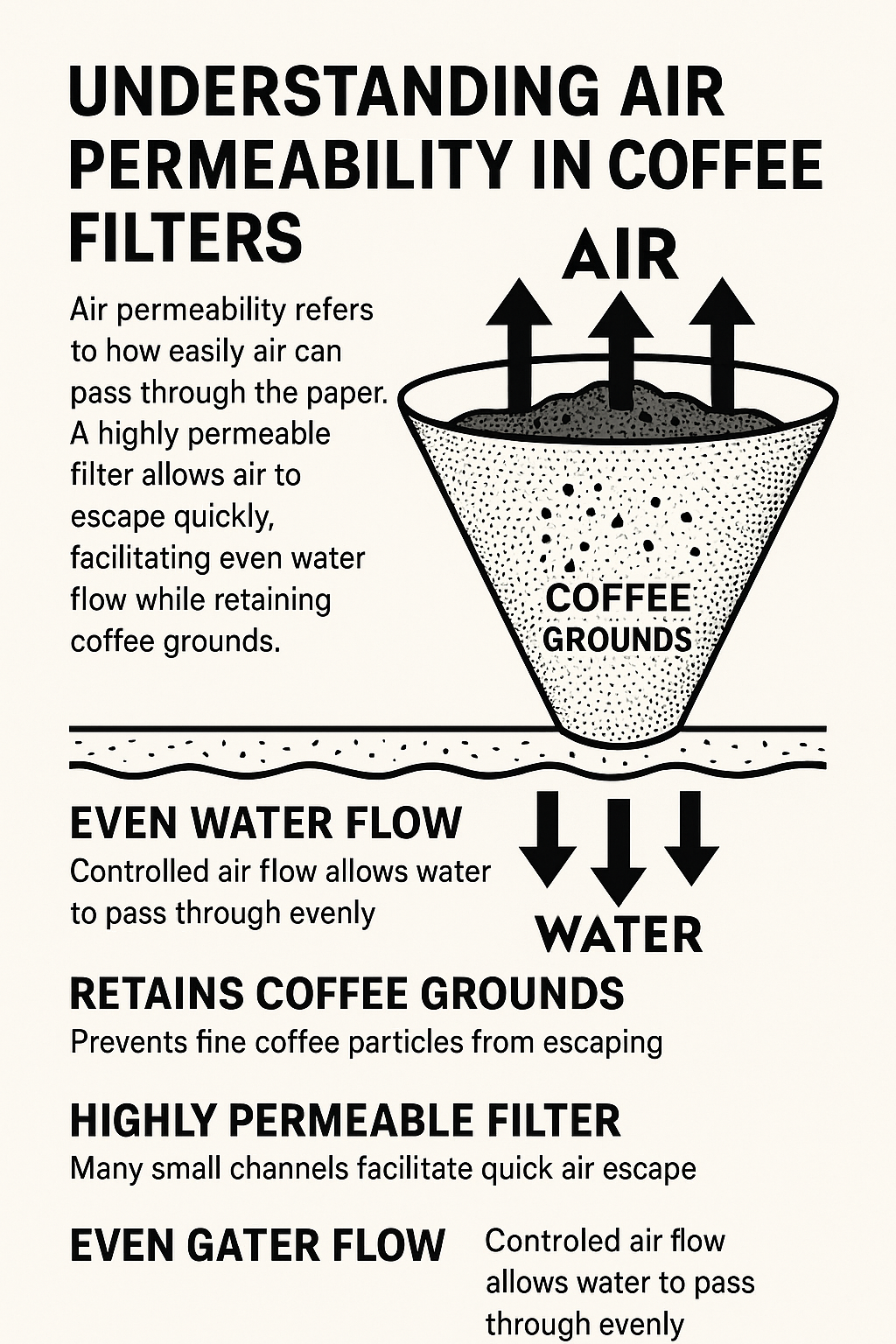

Understanding Air Permeability in Coffee Filters

Air permeability refers to how easily air (and thus water) can pass through the web of fibers in filter paper under pressure. It depends on the paper’s pore size, fiber composition, and thickness. A highly permeable filter has many tiny channels that let air escape quickly, while still blocking fine coffee grounds. In practical terms, air permeability is measured by standardized tests (for example, the Gurley or Bendtsen methods) that time how long a fixed volume of air takes to flow through a paper sample. For coffee filters, designers target specific permeability ranges: enough porosity to allow smooth water flow, but fine enough to catch sediment. Tonchant’s V60 filters are engineered with a precise fiber matrix – often using high-quality virgin pulp (FSC-certified wood pulp, bamboo or abaca blends) – so that the finished paper has a uniform network of pores. This uniformity ensures consistent air passages throughout the filter, which is critical for predictable brewing performance.

Air Permeability in the Brewing Process

In pour-over brewing, air trapped under the grounds must escape as water floods in. Proper air permeability lets that air flow upward through the filter paper, preventing a vacuum from forming beneath the coffee bed. As a result, water percolates evenly through the grounds rather than bypassing them. Filters with balanced air permeability create an optimal flow rate: not too slow to cause over-extraction, and not so fast that the coffee is under-extracted. This steady flow is essential for achieving a clean, flavorful brew. In practice, specialty filter papers often feature micro-crepe textures or very fine mesh, which form tiny grooves on the filter surface. These grooves maintain a layer of air along the filter wall, so air continuously escapes even as water percolates. The effect is a smooth, even drip with minimal channeling. Tonchant’s V60 filters use these principles by carefully controlling fiber laydown and forming processes, giving each filter a consistent rate of air flow. The result is reliable and reproducible pour-over brewing, cup after cup.

Air Permeability and Brewing Performance

Air permeability directly affects three key aspects of V60 brewing: flow rate, extraction balance, and flavor clarity. When a filter has the right permeability, the brew proceeds at a moderate pace, allowing water to interact fully with coffee grounds. This yields an even extraction, where both delicate aromatics and rich body components are drawn out. Conversely, a filter that is too dense (low permeability) can slow the flow excessively, causing sour or bitter notes from over-extraction. A filter that is too open (high permeability) lets water rush through, often producing a flat, underdeveloped cup. Proper air flow also helps trap unwanted solids: as water drains at a controlled rate, more suspended fines settle out, leaving a cleaner brew. Tonchant’s filters are calibrated to hit this sweet spot.

Key impacts of optimized air permeability include:

-

Steady Flow Rate: Controlled airflow prevents water from pooling or bypassing the grounds. Each pour yields a similar extraction time, making recipes easy to dial in.

-

Balanced Extraction: Uniform airflow means all grounds steep evenly. This avoids over-extracting some particles while others go under-extracted, leading to a more balanced, nuanced flavor profile.

-

High Flavor Clarity: With slow, stable drips, micro-fines and oils have time to stick to the paper. The cup is free of muddy sediment, highlighting the coffee’s clean acidity and aroma.

By tuning air permeability, Tonchant helps cafés and roasters achieve cups that are bright, full-flavored, and consistent. Every batch of Tonchant V60 filters is vetted to ensure these brewing qualities.

Tonchant’s Precision Testing and Quality Control

At Tonchant, quality starts before the coffee even arrives. The company maintains an in-house laboratory and state-of-the-art equipment dedicated to filter testing. Every production run undergoes rigorous checks for air permeability: specially calibrated instruments measure the rate of airflow through test strips, confirming that the filter paper meets exact performance targets. Tonchant tests hundreds of sheets from each batch to guarantee consistency. Other key quality controls include tensile (tear) strength tests, moisture analysis, and microbiological assays, all carried out under ISO 22000 (food safety) and ISO 14001 (environmental management) protocols.

Key quality measures at Tonchant include:

-

Precise Airflow Testing: Using industry-standard equipment (e.g. Gurley densitometers), Tonchant measures airflow per unit area at fixed pressure. This ensures each filter conforms to the designed permeability range for V60 brewing.

-

Uniform Fiber Selection: Only premium pulp sources (often imported Japanese wood pulp and natural fibers) are used. A controlled fiber blend yields a repeatable pore structure in every roll of paper.

-

Controlled Manufacturing: Automated refining, paper-forming, and calendering lines adjust sheet thickness and density with micron-level precision. This process control produces filters with identical basis weight and porosity from batch to batch.

-

Certifications and Standards: Tonchant filters comply with global safety and eco-standards (OK Compost, DIN-Geprüft, ASTM D6400, etc.), reflecting the company’s commitment to safe, sustainable products.

These technical capabilities mean Tonchant filter papers are not just ‘good on the drawing board’ – they are verified in every real-world use. Roasters can trust that a case of Tonchant V60 filters will perform the same as the sample.

Impact on Flavor Clarity, Flow Rate, and Extraction Balance

The science of air permeability translates directly into sensory results. When brewed through a Tonchant V60 filter with carefully balanced porosity, coffee tastes noticeably brighter and cleaner. The controlled flow rate promotes even extraction of sugars and acids without dragging out excessive bitter compounds. Fines (tiny coffee particles) are more efficiently trapped by the filter’s microstructure, which means fewer grounds or sludge in the cup and more clarity of flavor. In essence, Tonchant filters help define the end points of extraction so that the optimal flavor compounds are highlighted. Professional baristas and testers observe that coffee brewed on well-engineered, high-permeability filters exhibits a crisp finish and well-articulated notes. Tonchant’s design process – informed by lab testing and real brew trials – ensures each V60 filter supports these outcomes.

Tonchant’s Commitment to Technical Excellence and Quality

With over 15 years in food-grade paper production, Tonchant blends traditional craftsmanship with modern engineering. The company’s Shanghai-based factory (11,000㎡) features multiple production lines that serve customers globally, from single-cup labels to large roasteries. Tonchant invests in research and continuous innovation: a dedicated R&D center explores new fiber blends, filter geometries, and processing techniques to advance brewing science. Tonchant’s credentials are backed by independent certifications (ISO 22000, ISO 14001) and compliance with strict hygiene and biodegradability standards. This infrastructure and expertise mean that when Tonchant advertises precise air permeability and high service levels, it is supported by real-world capabilities.

Key strengths of Tonchant’s approach include:

-

Advanced Manufacturing: Continuous belt paper machines and precision calenders ensure filters are formed and dried under tightly controlled conditions, yielding consistent density and pore size.

-

Dedicated Test Lab: Tonchant’s in-house lab runs every crucial test – from airflow to tensile strength to microbial counts – so that customers receive only verified, high-quality filters.

-

Sustainable Materials: Only food-grade, chlorine-free pulp and natural fibers are used. The filters are 100% biodegradable and meet OK Biodegradable and ASTM compost standards, aligning with specialty coffee’s eco-friendly ethos.

-

End-to-End Service: Two integrated factories (material and packaging) allow Tonchant to offer competitive pricing without quality compromises, as well as services like dropshipping and small-batch orders to suit any client.

These capabilities reflect Tonchant’s commitment to supporting specialty brewers with science-backed products.

Customized High-Performance Filters for Every Brewer

Specialty roasters and cafés often have unique preferences and requirements. Tonchant excels at customization: clients can request filters of any size, shape, and material composition to fit their equipment and brewing style. Whether it’s standard V60 cones in multiple sizes, flat-bottom Kalita-style papers, or even custom-designed drip bag shapes, Tonchant can accommodate it. Customers can specify basis weight (paper thickness) to dial in the desired brew speed, or choose particular fiber blends (e.g. adding abaca or eco-friendly PLA fibers) to tweak filtration properties. Tonchant also provides OEM printing and private-label packaging services – making it easy for coffee brands to market a signature filter line. Other customization services include:

-

Filter Geometry: Precision stamping tools let Tonchant cut cone filters (for Hario V60, Origami, etc.), flat filters, or specialty bags. Each is tested for fit and performance.

-

Branded Packaging: Roasters can select custom box or pouch designs and count-per-pack, with low minimum orders. Tonchant’s design team helps finalize artwork and prototyping.

-

Rapid Sampling: With in-house production and lab facilities, Tonchant can turn around prototype samples in days. Adjustments to permeability or paper weight can be tested quickly before bulk production.

-

Flexible Order Sizes: Whether a boutique café needs a few thousand filters or a global chain orders millions, Tonchant’s factories scale accordingly without sacrificing consistency.

With this flexible approach, Tonchant ensures that every filter solution – from bleedless V60 cones to unique drip-bag formats – delivers the intended brew profile. The white V60 filters (shown above with fresh coffee beans) are bleach-free and precisely calendered for a crisp white finish, while natural (unbleached) filters are available for a more rustic, eco-conscious look. In all cases, the tailored filter meets the customer’s design goals and maintains the strict air permeability specs needed for high-performance brewing.

In summary, air permeability is a subtle but critical factor in V60 brewing, influencing flow rate, extraction, and flavor clarity. Tonchant’s science-driven filters are engineered and tested to get this balance right. By combining rigorous laboratory quality control, advanced materials, and flexible customization, Tonchant provides specialty coffee professionals with filter papers that unlock the best possible cup – clear in flavor, consistent in result, and aligned with each brewer’s needs.

Post time: May-31-2025