From Beans to Brand: The Ultimate Guide to Private Label Coffee Packaging

So, you have coffee beans, a perfect roast profile, and a brand you like.

Now comes the hardest part: putting it in a bag that looks professional enough to be displayed on the shelf alongside products from industry giants.

For many coffee businesses—from local cafes looking to sell merchandise to entrepreneurs launching online subscription services—private brands serve as a bridge between excellent products and scalable operations.

But where to begin? Do I need a machine? What kind of filter paper should I use? What is the minimum order quantity?

At Tonchant, we’ve helped hundreds of brands successfully navigate this process. We’ve compiled this guide to help you understand the key steps in building your own-brand coffee packaging strategy.

Step 1: Select Your Format (“Outline Dimensions”)

Before considering a logo, you need to determine how your customers will enjoy coffee. Private label brands are no longer limited to standard 1kg coffee bags.

-

The Single-Cup Coffee Revolution (Drip Coffee Bags): This is the fastest-growing sector. Drip coffee bags (drip filter bags) allow you to sell your premium roasted coffee in a convenient, portable format. They often command a higher price per gram than whole coffee beans.

Tip: For a high-end look, consider the UFO shape; for a more economical option, consider the classic square shape.

-

Whole Bean/Ground Coffee Packaging: The standard choice for home brewers. You’ll need to choose between flat-bottomed bags, four-sided resealable bags, or stand-up pouches (Doypack).

-

The “Complete Set”: Many successful brands now sell in “gift boxes”—for example, 10 drip bags packed in a beautifully printed outer box.

Step 2: Materials Are Important (Not Just Plastic)

Your packaging materials serve two purposes: to protect the coffee and to convey your values.

1. For Filter Cartridges (Drip Bags/Tea Bags)

If your brand prioritizes environmental protection, you cannot use regular nylon. You need to use PLA (corn fiber) or biodegradable nonwoven fabric.

-

Reality Check: Customers will ask if your filters are compostable. Be prepared to answer “yes”.

2. Outer Packaging (Roll Film)

Oxygen is the enemy of coffee freshness. For single-cup coffee, we recommend using high-barrier aluminum foil or aluminized film. These materials prevent oxidation and keep the coffee fresh for 12–18 months.

Tonchant’s Advantage: If you have your own machines, we can provide materials in roll film form; or, we can provide materials in pre-made bag form.

Step 3: Design and Printing (The Silent Salesman)

The old practice of simply sticking a sticker on a blank silver packaging bag is outdated. To stand out from the competition, you need custom printing.

-

Digital Printing: Ideal for small-batch production (low minimum order quantity). It delivers vibrant colors and allows for quick design modifications.

-

Gravure Printing: Ideal for high-volume printing. It offers the lowest unit cost and the highest print quality (matte, glossy, or soft-touch).

⚠️ Don’t forget the technical details: Your design needs to include space for the “cutting indicator” (the black square that tells the packaging machine where to cut). Tonchant’s design team will help you place this correctly to ensure your logo isn’t cut in half.

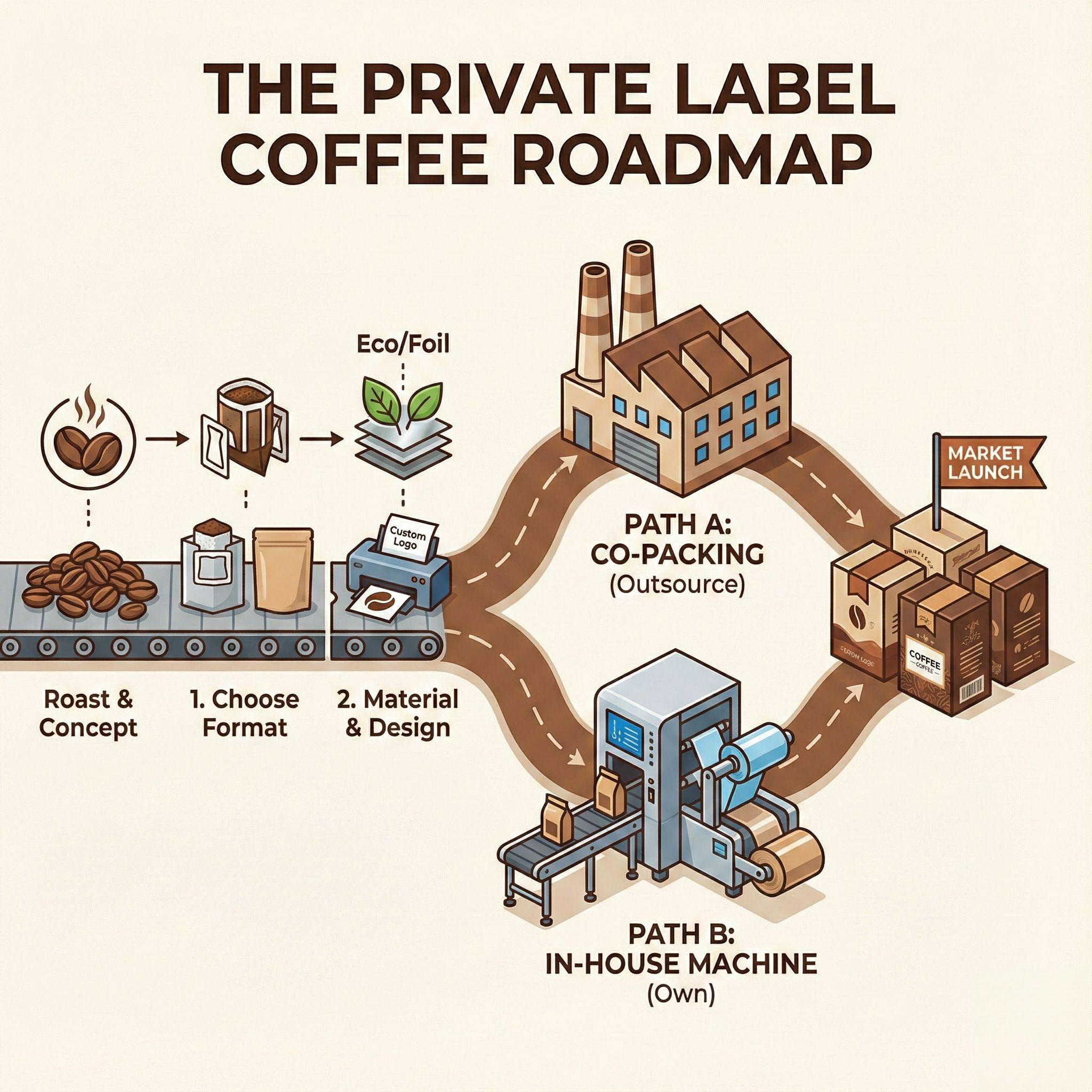

Step 4: A Critical Decision – Buy the Machine or Outsource?

This is the most critical business decision you will make.

Option A: OEM Packaging Service

You send us your roasted coffee beans. We grind them, use our machines and materials to pack them into drip bags, box them, and ship the finished product back to you.

-

Best suited for: Startups, testing new products, or brands that don’t want to manage a factory.

Option B: Self-Production (Purchasing Machinery)

You purchase packaging materials (filter paper and roll film) and automatic packaging machines from us. You produce the packaging bags in your own factory.

-

Best suited for: Established roasters with high production volumes.

-

ROI Note: Once sales reach a certain scale, the cost of purchasing the machine can be recovered quickly because the unit cost drops significantly.

Step 5: Nitrogen Purging (The Secret)

If you want to produce your own brand of drip bags, you must inquire about nitrogen.

Oxygen causes coffee to lose its freshness within a few days. The nitrogen rinsing process replaces the oxygen in the packaging with inert nitrogen before sealing. This keeps the residual oxygen content below 1%, allowing the coffee to retain its “freshly ground” aroma for over a year.

At Tonchant, our combined packaging lines and the machines we sell are equipped with high-standard nitrogen purging capabilities.

Ready to Build Your Brand?

Private label is more than just putting your name on a product; it’s about creating an experience.

Whether you need raw materials (filters and membranes), fully automated machines to run your own production line, or a partner to handle production for you, Tonchant is your one-stop solution.

Let’s talk about your project. [Contact Us] for inquiries about minimum order quantities, material samples, and equipment selection.

Post time: Dec-08-2025