If you run a production line, you’re definitely familiar with this sound.

The machine stops working. The alarm sounds. You walk over and find that the film has snapped again, or the seal isn’t closed properly, and coffee grounds are spilled everywhere.

For years, production managers have hesitated to switch to “eco-friendly” roll film due to this troubling issue. Early biodegradable or recyclable films were notorious for their handling difficulties. They were prone to stretching under tension, melting too quickly, or failing to provide a clean cut.

But the market has changed. There is no doubt that consumers (and regulators) are pressuring brands to abandon traditional multilayered plastics. The good news is that materials science has finally caught up with mechanical requirements.

At Tonchant, where we manufacture both packaging materials and packaging machinery, we understand that “green” film is useless if it doesn’t work properly. Here is why choosing the right engineered eco-film is the best upgrade you can make for your equipment this year.

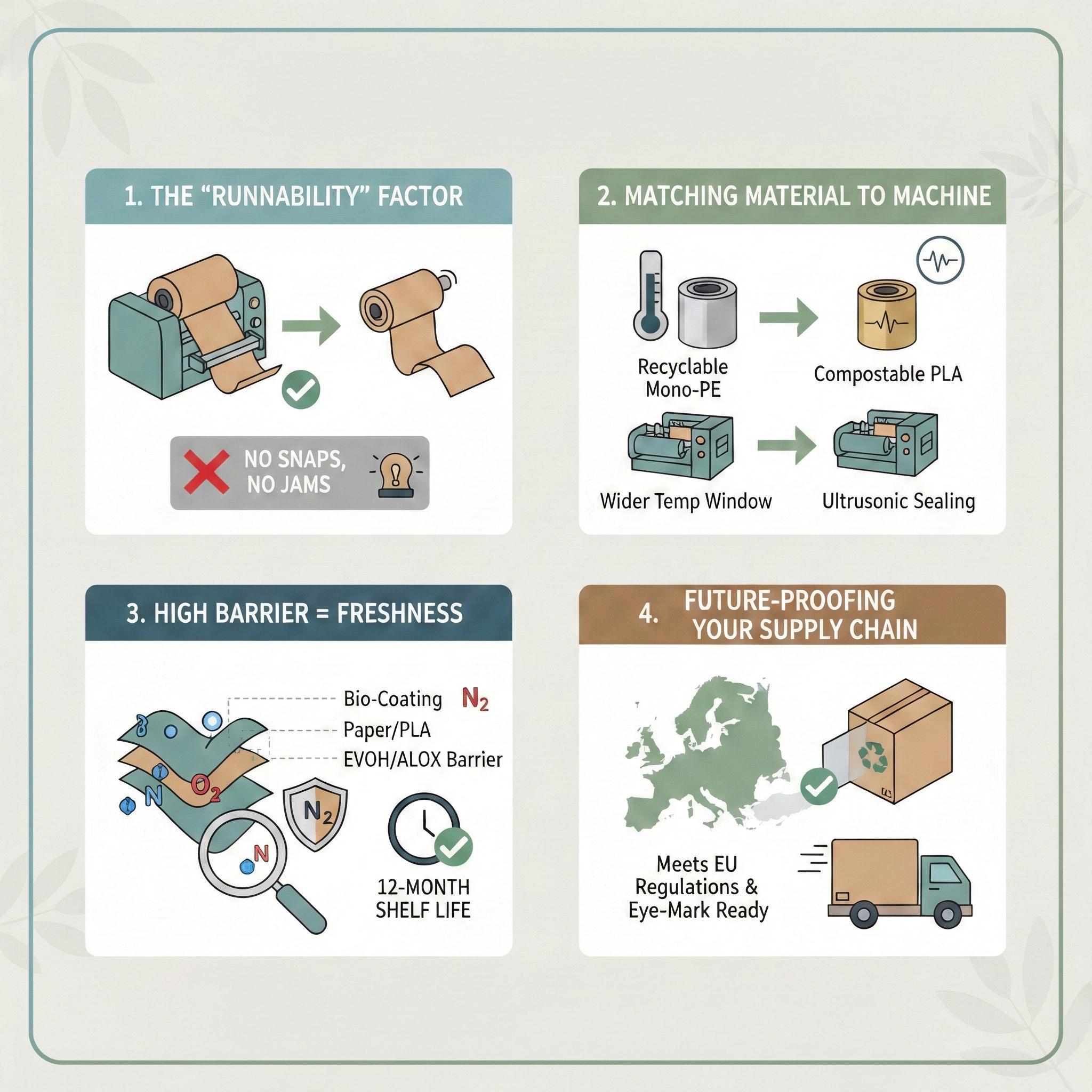

1. The “Runnability” Factor

When sourcing sustainable roll stock for your VFFS (Vertical Form Fill Seal) machines, “runnability” is the only metric that matters.

Inexpensive, generic eco-friendly films often lack thermal stability.

What makes Tonchant unique: Our eco-friendly films are crafted with special lubricants and a heat-resistant outer layer. Whether you choose recyclable single-layer polyethylene film or compostable PLA/paper film, our materials can withstand the tension and friction generated during high-speed automated production without breaking or curling.

2. Material Meets Machine: Sealing Technology

The biggest challenge facing green materials lies in controlling the Sealing Window. Traditional aluminum foil has a wide temperature tolerance, while eco-materials are more sensitive.

-

Recyclable (Mono-PE): Because it is made from a single material (polyethylene), it may stretch at excessively high temperatures. Our Mono-PE films incorporate a special polymer blend that expands the sealing window, making it easier for your machine operator to find the “optimal temperature” without melting the bag.

-

Compostable (PLA): PLA requires precise temperature control. If you are using Tonchant’s Ultrasonic Packaging Machine, our compostable film is ideal. Ultrasonic energy instantly bonds the film, preventing damage from heat shrinkage and ensuring a perfect hermetic seal every time.

3. High Barrier = Freshness

In the past, “environmentally friendly” meant “stale coffee.” Paper is naturally permeable to oxygen, which is a disaster for shelf life.

Today, we employ advanced high-barrier coatings. Our eco-friendly roll films feature EVOH or ALOX (Transparent Ceramic) coatings, achieving an Oxygen Transmission Rate (OTR) comparable to traditional aluminum foil.

The Result: You can use environmentally friendly materials while still guaranteeing your customers a 12-month shelf life.

4. Future-Proof Your Supply Chain

Sourcing roll film from a professional manufacturer like Tonchant can streamline your logistics.

Because we understand the specifications of packaging machinery (core size, roll width, and eye-mark position), we ensure that the roll material is a perfect match for your machine.

Furthermore, we can print “Recyclable” or “Compostable” certification logos directly onto the film, helping you meet the requirements of international labeling regulations such as the EU Packaging Directive.

Conclusion: It’s Time for a Change

You no longer need to choose between sustainability and efficiency.

Your packaging machine is a high-performance asset, and it deserves equally robust packaging film. Choosing Tonchant’s engineered eco-film reduces downtime, minimizes material waste, and provides your customers with the sustainable products they demand.

Unsure if our film is suitable for your machine? We offer test rolls. Please send us your machine specifications, and we will send you a sample roll for a trial run at your factory.

[Contact Tonchant Today to Request a Trial Roll]

Post time: Jan-27-2026